MAINTENANCE

Although clay feels slippery to the touch, it is quite abrasive on machine parts. The flywheel

press must be lubricated daily in all places where steel parts move: on the threaded shaft, the

die slides, the shaft die bearing, and the lower die rails. Periodically the press should be

stripped of oil, cleaned, and relubricated to remove residual grit from the slides and bearings.

The dies themselves are lubricated with each slab of clay (see Operation of a tile production

unit). Typically the joining of dip plates themselves determines the stopping place for the

flywheel. In pressing, sufficient clay is put into the press so a layer of clay is squeezed out

between the dies to avoid steel on steel contact of the die plates. Even so, the die plates do

wear down, and must be replaced after producing approximately one million tiles, depending

on the specific clay and tile design. In active Sri Lanka factories, this means every six

months.

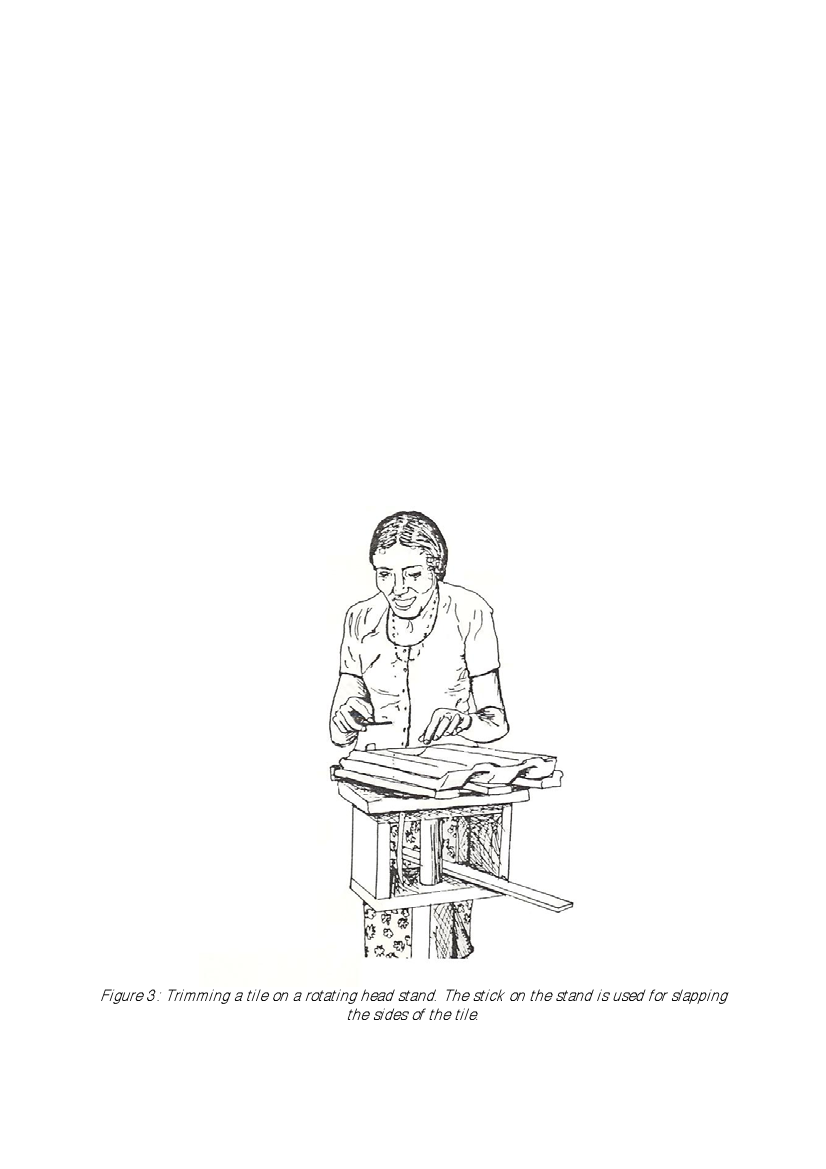

2.3 TRIMMING STANDS

The pressed tiles must be trimmed of flashing remaining from the moulding process (see

figure 3). To allow easy access to all sides of the tile a rotating stand head is used, so the

trimmer can stand in one place and turn the tile with ease. This type of head can be built in

many ways. Below is shown a common box head arrangement which is quite sturdy and easy

to construct.

Figure 3: Trimming a tile on a rotating head stand. The stick on the stand is used for slapping

the sides of the tile.